How is a Polychem system assembled and installed?

The following animation illustrates how a standard Polychem chain and flight scraper system is assembled and installed:

Go to Article

Scalable, efficient water clarification and biological treatment solutions that are thoroughly planned and fully supported through their entire lifecycle.

Brentwood’s fixed-film systems use structured-sheet media to deliver efficient and stable biological treatment for municipal and industrial wastewater applications. Our media modules are engineered to provide optimal treatment efficiency and an ideal environment for biofilm growth.

Learn More

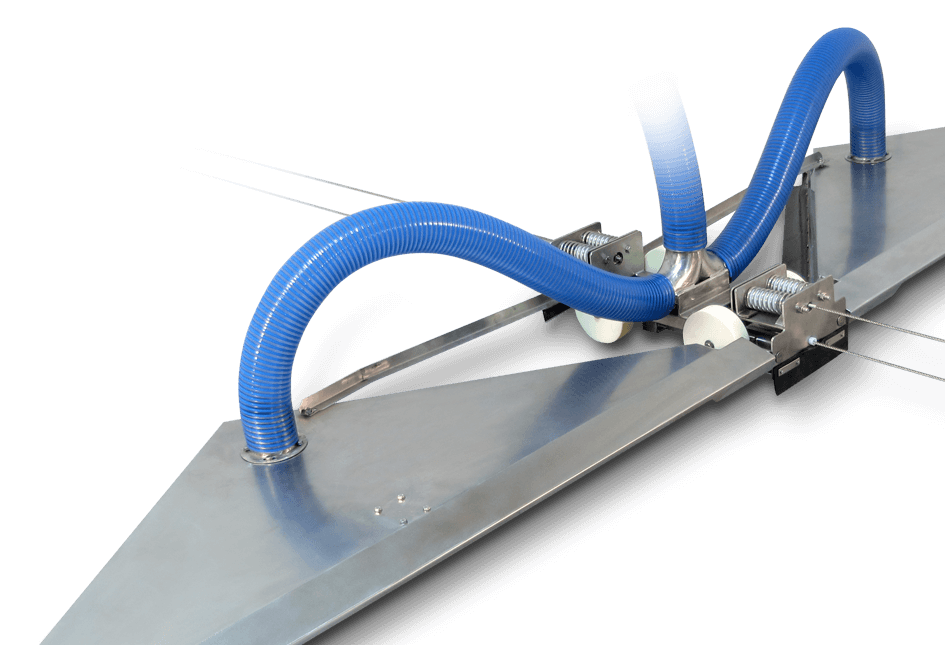

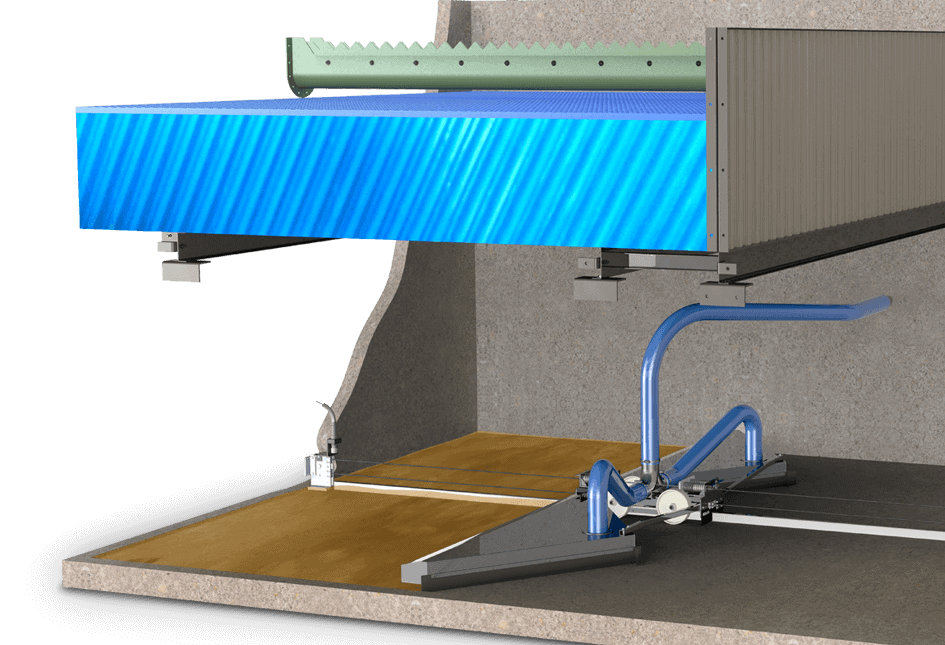

With more than 18,000 systems in operation, Polychem sludge collectors have become the industry standard for high performance and reliability. They feature plastic parts that provide a lightweight alternative to metallic components and have been engineered to function efficiently as part of any water or wastewater treatment system.

Learn More

The SedVac system features an innovative design capable of maintaining flow rates while resisting clogs. It handles heavy sediment and grit that traditional vacuum pipe systems leave behind, increasing plant capacity with minimal structural changes.

Learn More

Brentwood’s blue tubes integrate with our sludge collector systems to provide comprehensive clarification solutions. They are designed to increase treatment capacity without the large footprint and are engineered for maximum structural integrity.

Learn MoreColdwater, Michigan

When the Coldwater Board of Public Utilities received notice of a surprise change to ammonia permit limits, they faced a challenge. With limited budget and no room to add tanks at their wastewater treatment facility, the only viable option was to improve the performance of the IFAS process.

While IFAS has been a proven approach to problems like this, the Board issued an additional requirement: energy and operating costs had to be taken into account when selecting the aeration system, which is necessary for IFAS to work properly.

With so much on the line, Coldwater’s engineers needed proven results, not just empty promises. That’s when they turned to Brentwood.

The solution:AccuFAS.

Tiffin, Ohio

A booming agricultural economy and an outdated drinking water plant spelled big water quality problems for the town of Tiffin, Ohio. The resulting sedimentation and sludge problems were so bad, in fact, that water production was frequently disrupted, requiring costly and time-consuming tank cleaning every three weeks.

The Tiffin plant needed a solution that would automatically remove these solids, eliminating the need for manual cleaning, in the hopes of recovering lost revenue caused by downtime. They turned to Brentwood for answers, and the results were shocking.

The solution:SedVac.

Click on location pins to see installations.

The following animation illustrates how a standard Polychem chain and flight scraper system is assembled and installed:

Go to ArticleFrom the planning stage, to the manufacturing process, and through post-completion support—the experts at Brentwood are with you every step of the way. Complete the form below for more information about our Water & Wastewater treatment solutions.